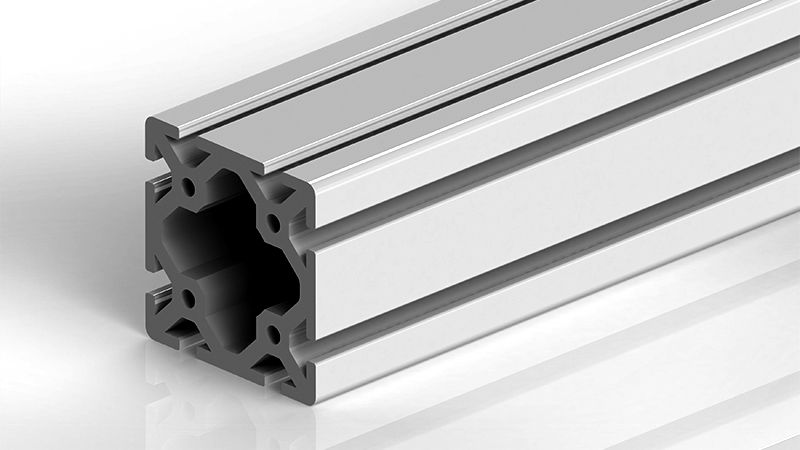

Our expertise and knowledge of working with aluminium allows us to suggest the best usage of complex shapes and features within the profile. This helps us eliminate machining steps, thus reducing the cost of the component.

FREEDOM OF DESIGN WITHOUT COMPROMISE

As a metal stockholder, our ability to globally source our extrusion gives Ateco a far greater choice of precision, size and quantity than when dealing with any one extrusion source. This gives complete freedom of design to our customers without fear of compromising the product because of the limitations of dealing with just the one extrusion supplier.

COST BENEFIT FROM INTELLIGENT SOURCING

Our customers’ design team often realise the benefits from the extrusion technologies available to Ateco which optimises their own ideas without compromise and can often make it possible to reduce the costs of the finished product.

PROTOTYPING AND SAMPLES

At Ateco we also offer a range of prototyping services. Please ask our team about 3D rapid prototyping, EDM wire eroded samples from aluminium stock, small quantity of parts machined from aluminium, or we can arrange to have a short production run of the actual aluminium extrusion which Ateco can then machine and finish ready for your prototyping trials.